Get Into Gears, Part 1

Published

Gears can be used for a number of different purposes, including: to increase or decrease speed, to increase torque, and to change the direction of movement.

In this post we look at some terms associated with gears and gear ratios, the main types of LEGO gears, and some techniques for analysing gear ratios and building with gears.

For more on this topic, see Get Into Gears, Part 2.

Talking about gears

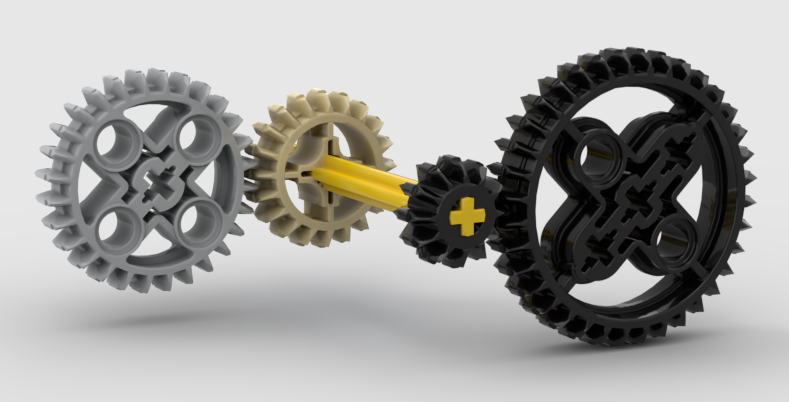

Two or more gears meshed together are called a gear train. The gear to which the force is initially applied is called the driver. In the picture below, the driver is turned by a crank. The final gear is called the follower. Any gears between the driver and the follower are called idlers.

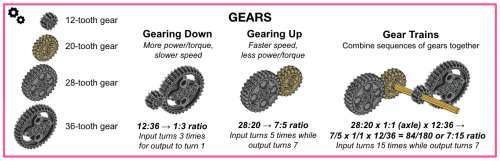

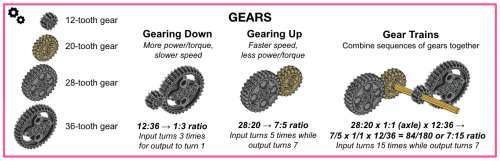

Gearing up means that the follower in a particular gear train turns faster than the driver. Gearing down means that the follower turns more slowly than the driver. In addition to changing the speed of the gears, gearing up or gearing down affects the torque, or turning force. Gearing down decreases the speed but increases the torque (making the gears easier to turn). Gearing up does the opposite, increasing the speed but decreasing the torque (and making the gears harder to turn).

The relative speeds at which the gears turn depends upon the number of teeth they have and is often expressed as a gear ratio. For example, an eight-tooth follower meshed with a forty-tooth driver will turn five times as fast as the driver (because 40 ÷ 8 = 5). If the gears are reversed, then the forty-tooth follower will turn five times more slowly than the eight-tooth driver.

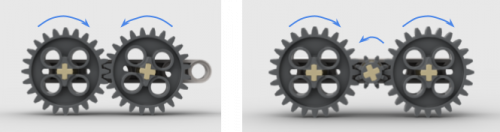

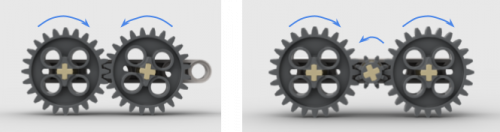

Idlers do not change the relative speeds of the driver and follower. They do, however, affect the direction. In a two-gear gear train, the driver and follower will turn in opposite directions. If a third gear, an idler, is placed between them, then the driver and the follower will turn in the same direction.

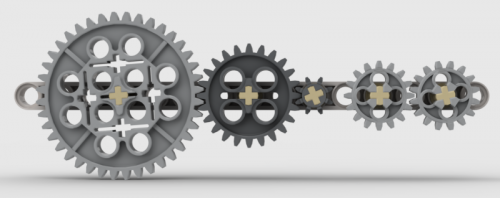

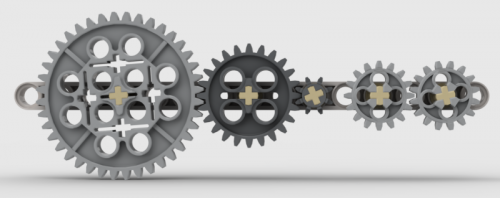

Gear trains can be stacked to form a compound gear. The total change in speed is the product of the speed change of each of the gear trains. For example, in this compound gear train, the white LEGO piece would turn 25 times as fast as the driver.

Types of LEGO gears

There are many different types of LEGO gears. They are typically categorised according to their overall shape as well as the shape and number of teeth.

Spur gears

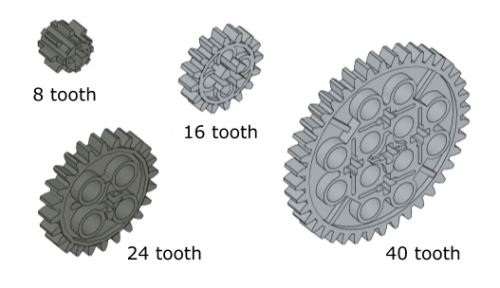

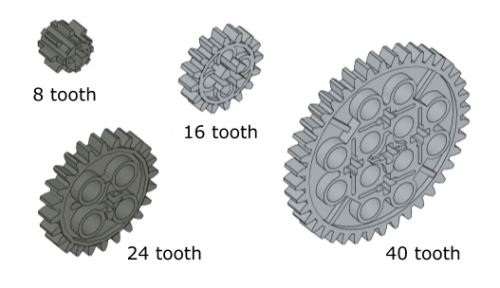

Spur gears are probably the most common and familiar type of LEGO gear.

The 40-tooth, 24-tooth, and 8-tooth gears will mesh with each other along a single beam. The 16-tooth gear can be meshed with the other gears, but not along a single beam. Two 16-tooth gears will, however, mesh with each other on a single beam.

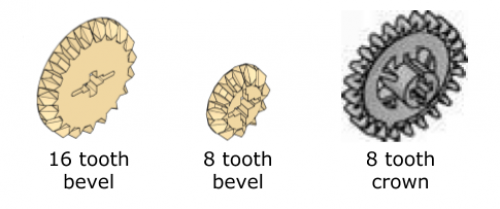

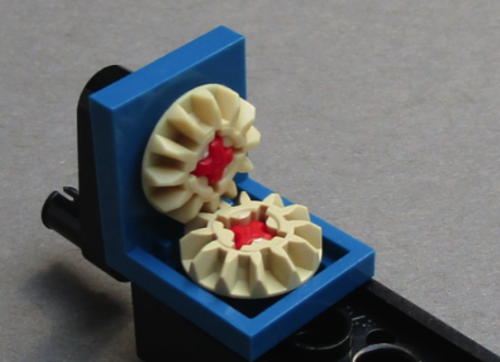

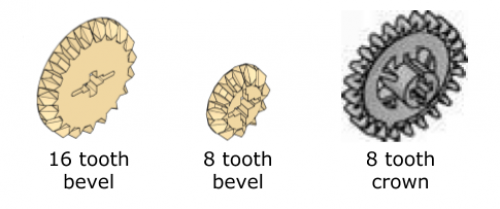

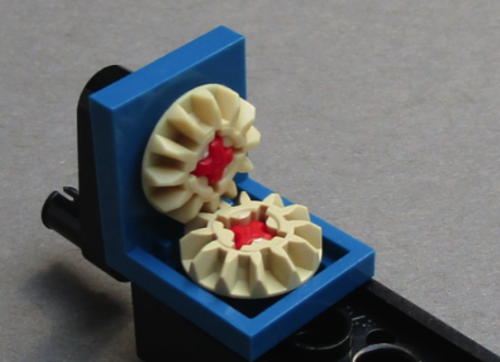

Bevel gears and crown gears

Bevel gears and crown gears are two types of gears that can be used to form right angles.

Bevel gears and crown gears can be meshed with other crown gears, spur gears, or double bevel gears to form a right angle.

Double bevel gears

Double bevel gears are particularly versatile and have become more common in recent LEGO sets, including the SPIKE Prime. Double bevel gears can be meshed with each other or with spur gears in the same plane or at right angles.

Many combinations of the double-bevel gears can be meshed along a single beam, but a few will not. For example the 36-tooth and the 20-tooth gears won’t mesh, nor will the 28-tooth and the 12-tooth. Try this for yourself.

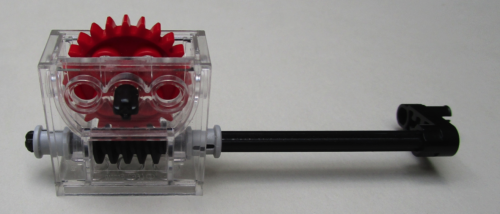

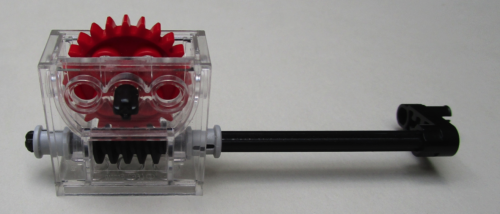

Worm gears

Worm gears can be thought of as single-tooth gears, with the tooth spiraled around a central shaft. They can be meshed with spur gears (or double bevel gears) to reduce speed and increase torque. For example, a 24-tooth spur gear meshed with a worm gear in a gearbox will move 24 times more slowly than the worm gear.

An important feature of a worm gear is that it is "one-directional" in that it can drive another gear but it can't be driven itself. If you haven’t come across this before, try it for yourself.

The one-directional nature of worm gears is a pretty handy feature if you want to be able to rotate an axle and have it “lock” in place when no power is being applied. Worm gears can be used for this purpose in a crane, a camera mount, or a stringed instrument such as a guitar.

See also this video on worm gears from Dr E’s Lab.

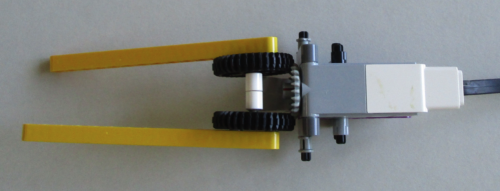

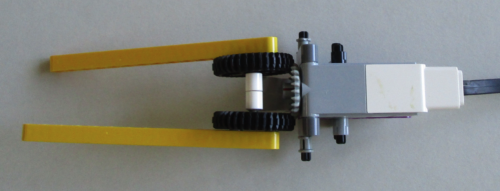

Rack and Pinion

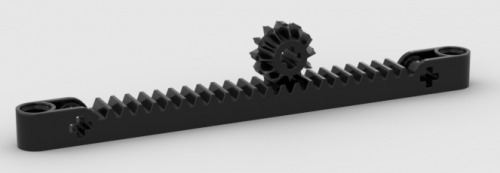

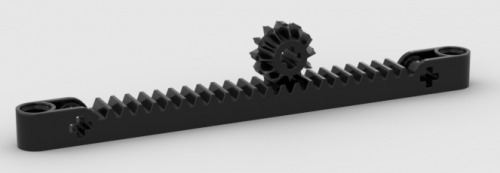

A rack and pinion is made up of two gears: a circular gear (the pinion) meshed with a linear gear (the rack). As the pinion rotates, it causes the rack to move back and forth.

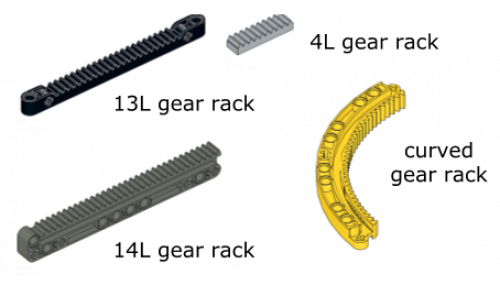

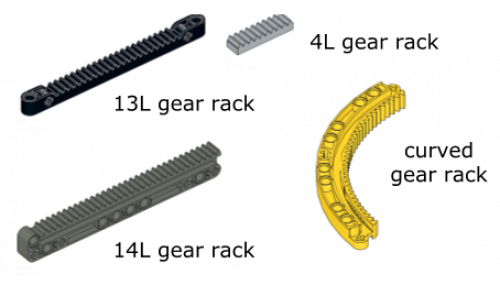

There are many different types of LEGO gear racks. Here is a small selection.

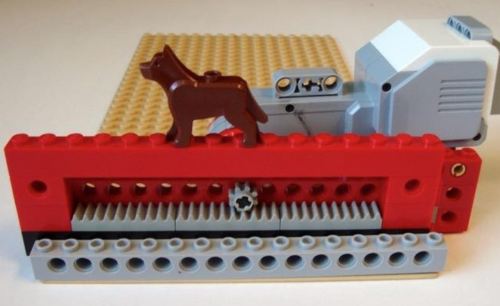

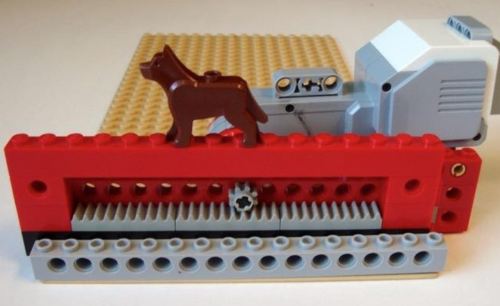

Rack-and-pinion mechanisms are often used for steering, but they can also be used anywhere that linear motion is desired. For example, here a motorized rack and pinion is used to move an animal back and forth:

Miscellaneous gears

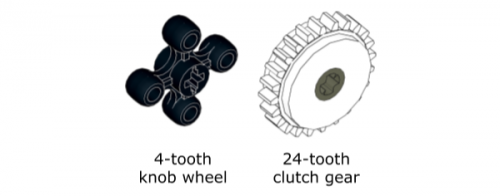

There are plenty more LEGO gears to explore, most of which are variations of the ones listed above, but here are two notable examples.

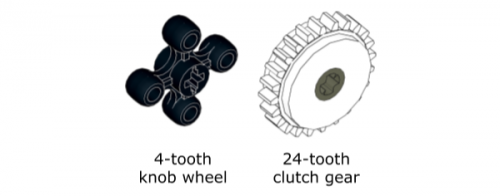

Four-tooth knob wheels mesh with each other on a single beam or at right angles. Because they don’t mesh with any other standard LEGO gears they’re not useful for gearing up or down, but they are great for transferring power in moderate to high torque situations.

The 24-tooth clutch gear consists of an inner and an out section that allow the axle to rotate freely if the outer part of the gear can't turn. This is useful, for example, to allow a motor to continue rotating if the mechanism that it is driving a mechanism is jammed.

Analysing gear trains and building with gears

For deep dive into analyzing gear trains, check out this series of videos from Dr E’s Lab. They primarily feature gears available in the EV3 set, but are good for walking through the process of calculating gear ratios. Of particular note is the part where a piece of ribbon is wrapped around the gears to measure the circumference and then layed out flat to present the ratio of different gears in a linear fashion. The following two videos focus on building strategies for assembling gear trains with offset gears as well as attaching gears to motors:

For more on this topic, see Get Into Gears, Part 2.

Thanks to Ethan Danahy and Barbara Bratzel for their contributions to this post.

In this post we look at some terms associated with gears and gear ratios, the main types of LEGO gears, and some techniques for analysing gear ratios and building with gears.

For more on this topic, see Get Into Gears, Part 2.

Talking about gears

Two or more gears meshed together are called a gear train. The gear to which the force is initially applied is called the driver. In the picture below, the driver is turned by a crank. The final gear is called the follower. Any gears between the driver and the follower are called idlers.

Gearing up means that the follower in a particular gear train turns faster than the driver. Gearing down means that the follower turns more slowly than the driver. In addition to changing the speed of the gears, gearing up or gearing down affects the torque, or turning force. Gearing down decreases the speed but increases the torque (making the gears easier to turn). Gearing up does the opposite, increasing the speed but decreasing the torque (and making the gears harder to turn).

The relative speeds at which the gears turn depends upon the number of teeth they have and is often expressed as a gear ratio. For example, an eight-tooth follower meshed with a forty-tooth driver will turn five times as fast as the driver (because 40 ÷ 8 = 5). If the gears are reversed, then the forty-tooth follower will turn five times more slowly than the eight-tooth driver.

Idlers do not change the relative speeds of the driver and follower. They do, however, affect the direction. In a two-gear gear train, the driver and follower will turn in opposite directions. If a third gear, an idler, is placed between them, then the driver and the follower will turn in the same direction.

Gear trains can be stacked to form a compound gear. The total change in speed is the product of the speed change of each of the gear trains. For example, in this compound gear train, the white LEGO piece would turn 25 times as fast as the driver.

Types of LEGO gears

There are many different types of LEGO gears. They are typically categorised according to their overall shape as well as the shape and number of teeth.

Spur gears

Spur gears are probably the most common and familiar type of LEGO gear.

The 40-tooth, 24-tooth, and 8-tooth gears will mesh with each other along a single beam. The 16-tooth gear can be meshed with the other gears, but not along a single beam. Two 16-tooth gears will, however, mesh with each other on a single beam.

Bevel gears and crown gears

Bevel gears and crown gears are two types of gears that can be used to form right angles.

Bevel gears and crown gears can be meshed with other crown gears, spur gears, or double bevel gears to form a right angle.

Double bevel gears

Double bevel gears are particularly versatile and have become more common in recent LEGO sets, including the SPIKE Prime. Double bevel gears can be meshed with each other or with spur gears in the same plane or at right angles.

Many combinations of the double-bevel gears can be meshed along a single beam, but a few will not. For example the 36-tooth and the 20-tooth gears won’t mesh, nor will the 28-tooth and the 12-tooth. Try this for yourself.

Worm gears

Worm gears can be thought of as single-tooth gears, with the tooth spiraled around a central shaft. They can be meshed with spur gears (or double bevel gears) to reduce speed and increase torque. For example, a 24-tooth spur gear meshed with a worm gear in a gearbox will move 24 times more slowly than the worm gear.

An important feature of a worm gear is that it is "one-directional" in that it can drive another gear but it can't be driven itself. If you haven’t come across this before, try it for yourself.

The one-directional nature of worm gears is a pretty handy feature if you want to be able to rotate an axle and have it “lock” in place when no power is being applied. Worm gears can be used for this purpose in a crane, a camera mount, or a stringed instrument such as a guitar.

See also this video on worm gears from Dr E’s Lab.

Rack and Pinion

A rack and pinion is made up of two gears: a circular gear (the pinion) meshed with a linear gear (the rack). As the pinion rotates, it causes the rack to move back and forth.

There are many different types of LEGO gear racks. Here is a small selection.

Rack-and-pinion mechanisms are often used for steering, but they can also be used anywhere that linear motion is desired. For example, here a motorized rack and pinion is used to move an animal back and forth:

Miscellaneous gears

There are plenty more LEGO gears to explore, most of which are variations of the ones listed above, but here are two notable examples.

Four-tooth knob wheels mesh with each other on a single beam or at right angles. Because they don’t mesh with any other standard LEGO gears they’re not useful for gearing up or down, but they are great for transferring power in moderate to high torque situations.

The 24-tooth clutch gear consists of an inner and an out section that allow the axle to rotate freely if the outer part of the gear can't turn. This is useful, for example, to allow a motor to continue rotating if the mechanism that it is driving a mechanism is jammed.

Analysing gear trains and building with gears

For deep dive into analyzing gear trains, check out this series of videos from Dr E’s Lab. They primarily feature gears available in the EV3 set, but are good for walking through the process of calculating gear ratios. Of particular note is the part where a piece of ribbon is wrapped around the gears to measure the circumference and then layed out flat to present the ratio of different gears in a linear fashion. The following two videos focus on building strategies for assembling gear trains with offset gears as well as attaching gears to motors:

For more on this topic, see Get Into Gears, Part 2.

Thanks to Ethan Danahy and Barbara Bratzel for their contributions to this post.

Blog Think Like An Engineer

11/08/2020 11:14pm EST

Leave a Comment

Thanks so much for this! This is a great resource for students & teachers alike!

This is awesome, thanks so much for putting this material together!

I think there is an error in the captions in one of your images. The “gearing up” and “gearing down” titles are above the wrong configurations. I think they are swapped by mistake.

Well spotted - have fixed this now, thanks!